Meet the problem solvers

The synthetic biologists finding solutions to environmental problems by reusing waste products.

The latest Intergovernmental Panel on Climate Change (IPCC) report calls for urgent action to avoid global temperature rises above 1.5°C. Radical change in the use of fossil fuels, waste management and recycling are required to reduce greenhouse gas emissions. Dr Louise Horsfall and her team are harnessing the power of biology to recover valuable resources from contaminated land and industrial waste, in a quest to find solutions to the world’s environmental problems.

By Monica Hoyos Flight

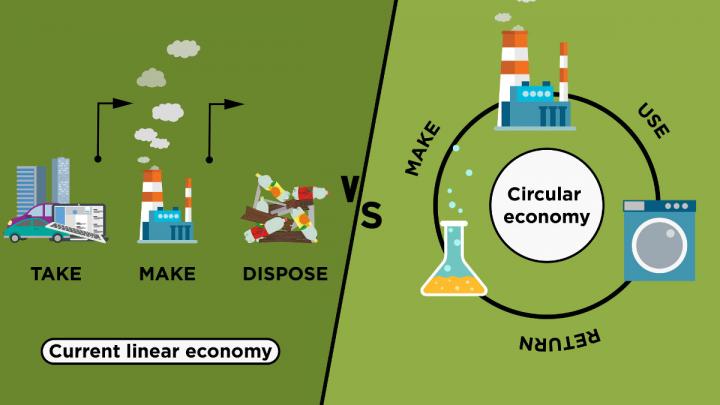

As the global population grows, so does our waste and demand for natural resources. One actively pursued solution is to move away from the current linear economy, in which we extract, produce, consume and discard resources, to a circular economy that sees waste not as a problem, but as a raw material to reuse in future goods.

According to environmental think tank Green Alliance, the UK currently exports seven million tonnes of steel scrap every year and is 100 per cent reliant on imports of raw materials like rare earth elements and cobalt for producing high-tech products and developing renewable energy technology. Recovering these materials from discarded products, which would otherwise be wasted or exported, could supply more than a third of domestic rare earth element demand and cut carbon emissions from steel production by around 30 per cent.

The IPCC prediction that we have 12 years to avert a “climate catastrophe” highlights that the time to act is now. As Dr Louise Horsfall, Director of the University’s MSc in Synthetic Biology & Biotechnology and elected co-chair of the Bioengineering and Bioprocessing section of the European Federation of Biotechnology, explains: “The realisation that we are reaching the end of easily accessible resources and that we need to reuse and repurpose seems to finally be hitting home.”

Since 2015, when the European Commission adopted a Circular Economy Action Plan to stimulate Europe’s transition towards a circular economy, 54 actions have been delivered or are being implemented. Over the period 2016– 2020, the Commission is investing more than €10 billion in public funding to the transition to boost Europe’s global competitiveness and foster sustainable economic growth.

The realisation that we are reaching the end of easily accessible resources and that we need to reuse and repurpose seems to finally be hitting home.”

Looking outside the EU, China and Japan are also committing to transition to a circular economy, and not just by improving waste management but also by introducing eco-friendly design criteria that reduce the addition of hazardous substances during manufacturing and increase product lifespan. China’s import ban on 24 types of waste in 2018 injected new momentum into the improvement of recycling systems in many countries, including the UK.

Technologies supporting a circular economy

A whole range of technologies are being applied to improve manufacturing processes and waste management; from digital technologies focusing on computer science, electronics and communication, to physical and chemical technologies that explore how the basic properties of materials can be exploited to make production and recycling more sustainable. However, it is biological technologies that are providing the most transformative solutions to the challenges posed by the transition to a circular economy.

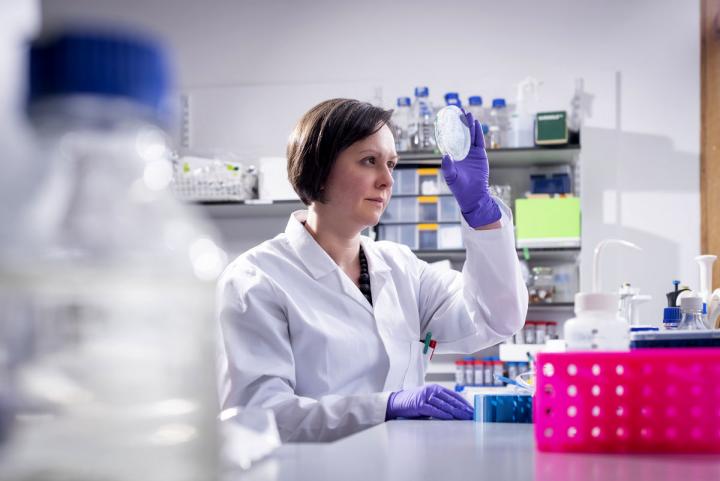

The Horsfall Lab is working at the frontier of biology and engineering to create microorganisms that can extract reusable materials from industrial by-products or contaminated land. “Biology is incredibly specific and selective; our aim is to harness and improve these properties so that they can be put to other uses, affordably and effectively,” says Dr Horsfall.

Synthetic biology uses engineering principles to design, build and test new biological systems for useful purposes. It has been described as a disruptive technology at the heart of the fourth industrial revolution, capable of delivering biological devices and systems with potential applications in energy production, environmental protection and healthcare. The UK Government has invested heavily in synthetic biology as one of the country’s eight great technologies that will provide significant long-term benefits for the economy and society.

The University is internationally recognised for its synthetic biology research, which has more than £50 million in investment and 40 multidisciplinary research groups with world-class capabilities in this exciting area of technology. It also hosts the Edinburgh Genome Foundry, a BBSRC funded national facility that can design and assemble genetic material on an unprecedented scale using a fully automated robotic platform. Extensive collaborations with industry allow researchers to address real-world problems and create new business opportunities.

Cleaning land for wealth

Dr Horsfall’s research has contributed to a nationwide project aiming to incentivise the decontamination of land. Following phytoremediation, that is the removal of heavy metals from contaminated land using natural plant varieties, her lab explored ways to effectively extract the heavy metals from these plants so they can be reused.

“We found that particular bacterial strains are able to extract dissolved nickel, one of the major soil contaminants in the UK, from biomass produced in phytoremediation and produce high-value nanoparticles that can be easily removed from a solution,” she says. Such tiny particles can be used as catalysts in hydrogen fuel cells or as antimicrobial agents, thus improving the economic viability of cleaning up contaminated land.

In addition to nickel nanoparticles, researchers in her lab are also studying bacteria that can produce nanoparticles of other valuable metals, such as platinum and palladium. At present the process is carried out in laboratory conditions, but the aim is to make it economically viable so it can be carried out at an industrial scale. This can be achieved by enhancing the efficiency of nanoparticle production, so that more metal ions are extracted from a sample, and by improving nanoparticle utility by increasing the production of particles that are uniform in size and shape.

Understanding the mechanisms through which bacteria make these metal nanoparticles will not only allow researchers to optimise the conditions for the process to take place, but also enable them to improve the process at the genetic level.

Deriving value from industrial by-products

Metal-nanoparticle-producing bacteria can have many uses besides decontaminating land. In collaboration with industry, Dr Nick Pantidos, an Edinburgh biotechnology graduate and postdoctoral researcher in Dr Horsfall’s lab, is exploring the use of bacteria to extract copper from whisky distillery by-products.

“Copper ions are toxic to most living organisms, but some microorganisms have developed a defence system against that,” Nick explains. “By converting copper ions to more inert copper nanoparticles they can survive in environments where other organisms cannot and we can take advantage of this to make the disposal of whisky by-products safer.”

Not only that, it could lead to new revenue streams for distilleries as the copper nanoparticles could be sold for the production of antimicrobial coatings, transistors, solar cells and LEDs. Large distilleries producing up to one kilogram of copper nanoparticles a day could make more than £5,000 from them.

Lignin is another interesting waste product as, after cellulose, it is the most abundant renewable carbon source on Earth. If broken down efficiently, it could be a very valuable source of aromatic chemicals that are currently derived from fossil fuels. It is a major component of the waste biomass produced by the biofuel, food and paper industries but it is extremely resistant to chemical or physical degradation due to its rigid structure.

“At present ‘waste’ lignin is burnt to fuel industrial processes. Breaking down lignin to generate useful, high-value and sustainable chemicals is a major part of improving the sustainability of these industries,” says Zak Towle, a quantitative biology, biochemistry and biotechnology PhD student in Dr Horsfall’s lab. He is investigating how some microorganisms are able to degrade lignin and ways to accelerate this naturally occurring process by genetically engineering bacteria and yeast.

“Compared with physical and chemical approaches that generally require a lot of heat, pressure and solvents, biological approaches offer a cheaper, more environmentally friendly and, potentially, more predictable way of breaking down lignin,” he adds.

We’re seeing a perceptible shift away from asking what we can do with waste to asking how we can redesign products and systems so they never create waste in the first place.

Tackling battery waste problems

The lab is also exploring the bio-recovery of metals from spent batteries. The growing environmental and health hazards of conventional mining methods for extracting metals that power electronic devices inspired Yuta Era, a first-year PhD student at Edinburgh who gained his undergraduate degree in mining engineering from Kyushu University in Japan, to explore the use of biological processes to recover metals from dissolved battery waste. “Louise’s lab was a perfect match for my research interests,” he says.

By optimising how bacteria can extract specific metals from solution, he aims to improve the security of future sources of palladium, platinum, nickel and cobalt. The Japanese Government will be contributing to fund Yuta’s project as he explains: “Japan and the UK are similar in the sense that they have large motor and electronics industries but are poor in natural resources, so both countries need solutions to meet the growing demand for metals.”

Anticipating this issue, the UK Government’s Industrial Strategy Fund launched the Faraday Battery Challenge to support research into the production of cheaper, longer-lasting and recyclable batteries. Further research into lithium-ion battery technology in particular is crucial to meet the government’s ambition to replace conventional petrol and diesel vehicles with electric and zero emissions vehicles by 2040.

“To meet the exponential demand for lithium-ion batteries we need to ensure that we will have access to the raw materials required for producing them,” says Dr Virginia Echavarri-Bravo, a postdoctoral researcher working on one of the first Faraday Institution projects. The Recycling of Lithium-Ion Batteries (ReLiB) project sees Dr Horsfall’s lab collaborating with the University of Birmingham to improve the safety, economics and efficiency of battery recycling while minimising the environmental impact of these processes.

“Our aim is to recover metals from disassembled lithiumion batteries and separate one from each other using a combination of physical, chemical and biological methods,” she explains. Her work focuses on characterising the mechanisms through which different bacterial species can extract specific metals and produce reusable nanoparticles.

“It is immensely rewarding to work towards environmentally friendly solutions to real-world problems in collaboration with other universities in the UK and industrial partners,” she says.

Building momentum

“There was virtually no awareness of the circular economy seven years ago, but now it seems to be on everyone’s agenda – governments, businesses, universities, community groups...” says Colin Webster, an Edinburgh alumnus who is now Learning Content Manager at the Ellen MacArthur Foundation, a charity launched in 2010 to accelerate the transition to a circular economy. “We’re seeing a perceptible shift away from asking what we can do with waste to asking how we can redesign products and systems so they never create waste in the first place.”

According to Joyce Tait, co-Director of the Innogen Institute at the University, and member of the Synthetic Biology Leadership Council and the Council for Science and Technology that advises the Prime Minister on science and technology policy issues, synthetic biology is a key driver of the circular economy. “The Horsfall lab is working at the cutting edge of a wide range of disciplines to deliver solutions for the UK bioeconomy and contributing to the aims of the UK’s Strategic Plan for Synthetic Biology, which sets out a clear path to ensure the UK maintains its position as a global leader in this field,” she says.

“So far, synthetic biology has only led to incremental advances and is not even close to delivering its full potential,” says Dr Horsfall. “We are at an extremely exciting time; we are just starting to push the boundaries and establish new multidisciplinary collaborations looking beyond the element carbon to explore a myriad of ways to help us transition to a circular economy.”

About the writer: Dr Monica Hoyos Flight is a freelance science writer and previously worked as Research Administration & Communications Manager at the University’s Roslin Institute.

Find out more