Blog - Producing heat-stable blue natural colourant from cyanobacteria

Did you know that the blue colour of ice cream can come from blue-green algae? PhD student Apple Chew discusses Anton Puzorjov’s research in producing a new heat-stable variant of a natural blue colouring.

(Author: Apple Chew, Editor: Aranza Diaz)

We can all name classic blue-coloured foods (a certain chocolate comes to mind..). These have traditionally been made blue through using articifical colourings like Blue no.1, but there is now increasing demand to use natural food colourings instead. PhD student Anton Puzorjov here in IMPS is investigating a compound from cyanobacteria, also known as blue-green algae, for use as a natural blue colouring for food, beverages and cosmetics.

Did you know that it’s not just plants that can produce energy and oxygen using light and carbon dioxide (a process called photosynthesis)? Cyanobacteria, also known as blue-green algae, are bacteria that are able to photosynthesise. We find cyanobacteria in different types of water environments around the world, and they play an important role in regulating oxygen and carbon dioxide levels in our atmosphere. Cyanobacteria were actually the first organisms to evolve that could produce oxygen and are thought to have converted the Earth’s early oxygen-poor atmosphere into an oxygen-rich one, causing the Great Oxygenation Event 2,300 million years ago! The way that cyanobacteria carry out photosynthesis is different to plants as they don’t have chloroplasts. Instead, they use a protein complex called a phycobilisome to “harvest” light for use in photosynthesis. One of the proteins in the phycobilisome is called phycocyanin and it has a bright blue colour.

Phycocyanin is already extracted from cyanobacteria and is usually processed into a powder form. An example of this is the phycocyanin extracted from Spirulina, a well-known cyanobacteria, marketed under the brand names ‘ScotBio Blue’, 'Lina Blue' or 'EXBERRY® Shade Blue'. This can be found in sweets and ice cream products sold in markets. It also has applications in anti-ageing, anti-cancer and even anti-viral treatments thanks to its anti-oxidant properties. However, there is a huge issue with commercially available phycocyanin: it breaks down at high temperatures (exceeding 45 °C). This causes problems with extraction and its use in commercial products because it loses its blue colour and its antioxidant properties.

To tackle this problem Anton has turned to nature for inspiration. A heat-stable phycocyanin protein can be found in heat-loving cyanobacterium called Thermosynechococcus elongatus that was originally found in Japan’s hot springs. We can’t just use T. elongatus to produce phycocyanin as it is hard to grow (it needs hot temperatures!). So, Anton developed a way to produce T. elongatus heat-stable phycocyanin using lower temperatures (you can read his published research in the journal of Metabolic Engineering Communications).

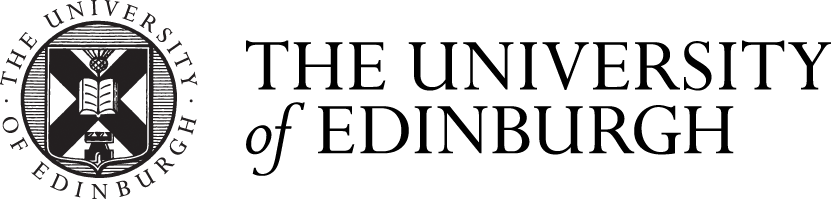

Anton's idea involved using a cyanobacteria that grows at a lower temperature of 30oC. This species, called Synechocystis, was chosen because it can easily be grown and engineered. Anton used, genetic engineering techniques to transfer the genes that code for the T. elongatus heat-stable phycocyanin into a Synechocystis mutant strain called Olive, which had its own phycocyanin genes deleted. The genes were transferred via a technique called bacterial conjugation where two bacterial cells make a bridge-like connection between two cells and transfer DNA from one cell to another (you can watch Anton’s protocol for this here: Journal of Visualized Experiments).

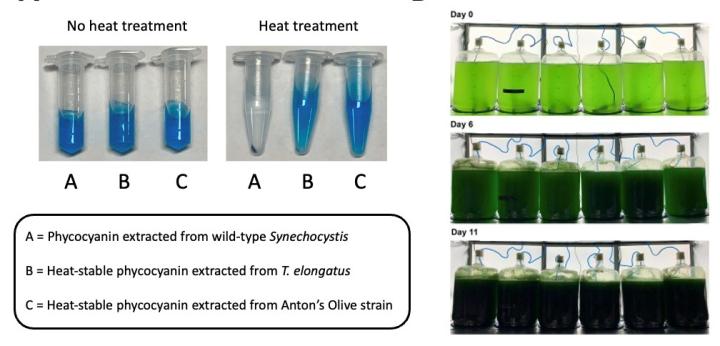

Surprisingly, there were several advantages of producing the heat-stable phycocyanin in Olive. First, Anton observed that it significantly improved the growth rates of Olive, suggesting that heat-stable phycocyanin can be used by Synechocystis to absorb light energy. The phycocyanin was also much easier to extract! Current phycocyanin purification processes include the use of complicated technology to seperate out the different proteins in the cyanobacteria cells, this is very expensive and difficult to scale up, making phycocyanin more expensive to buy.

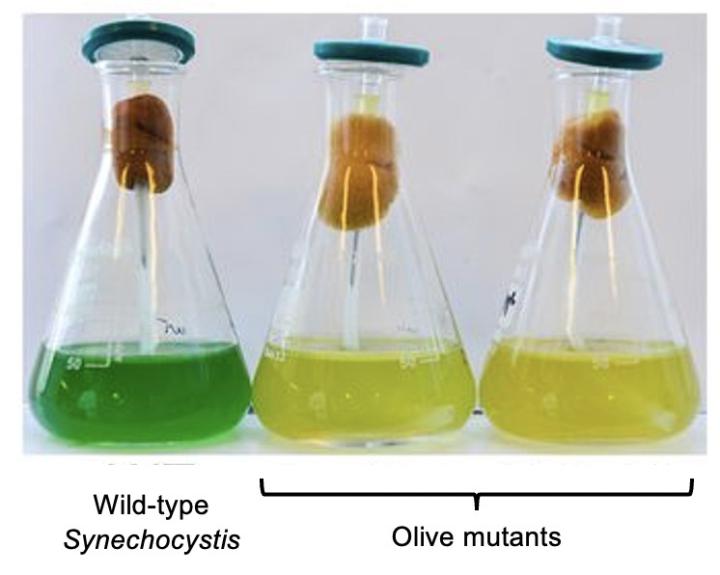

After harvesting his engineered Olive strain and extracting its phycobilisome, Anton heated the cell extract at a high temperature. This process not only degraded the unwanted proteins but left the heat-stable phycocyanin intact and functional. This simple, low-cost protein purification step using heat treatment makes extraction and purification much easier to scale, allowing us to produce lots of pure phycocyanin.

Anton says that the biggest challenge of his research was to learn the techniques required to characterise the Synechocystis strain Olive that can make the heat-stable phycocyanin. What was amazing was that he was able to prove viability of producing and purifying the heat-stable blue pigment at a low cost. He has also been able to win extra funding to test further scaling-up of his method to see if it could be commercially viable which is very exciting. So perhaps one day you will see his method being used to produce all sorts of blue products!

If you would like to find out more information and details about this project you can read more here: Bioresource Technology.